Once the clinical examination with the patient comes to an end, it's time for the creation process to begin. That's when the PODOLAB® Master becomes the ultimate assistant for making insoles! A device that optimises your working time, adapts to all working methods, and is scalable according to your business and the number of practitioners using it.

PODOLAB® Master: an innovative thermoforming device

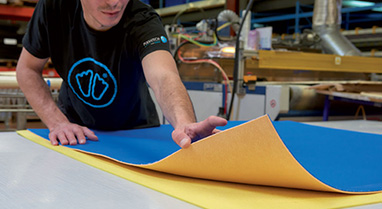

The thermoforming of orthotic insoles has never been easier or more optimised thanks to the PODOLAB® Master. Its smart control and adjustment functions make thermoforming your insoles child's play. Its large heating plate can accommodate insoles up to size 55. You can also choose to apply heat to only two-thirds of the surface in order to protect certain materials at the forefoot, or to the entire surface depending on the desired results. With a heating range of 70 °C to 200 °C, you can thermoform a wide variety of materials. Being compact and stylish, it will fit perfectly into your practice, whatever the available space or layout.

With 4 customisable saved options, the PODOLAB® Master saves you precious time when designing orthotic insoles. A single button launches the entire pre-saved procedure: temperature, heating time, heat surface, as well as cooling time for postural insoles. To save even more time, you can use the ventilation option to reduce the cooling time of your postural or moulded insoles by 50%. The supplied Teflon protector will ensure the cleanliness and efficiency of the PODOLAB® Master, protecting the plate and heating circuit during use.

The PODOLAB® Master is scalable thanks to its cast and heat extensions to adapt to your business and techniques over time.

Cast and heat extensions: upgrade your PODOLAB® Master

The PODOLAB® Master grows with your business thanks to its two extensions, allowing you to increase the working surface without switching thermoforming device.

The heat extension will allow you to double your work surface by obtaining a double tray to perform heating and pressurising.

The cast extension will give you a 2nd (unheated) surface that allows you to make your orthotics on positive using its vacuum and deeper tray.

The smart and innovative PODOLAB® Master system and its extensions scale to your work as your business grows and the number of practitioners increases.

Designed for all production techniques

The individualised control of each tray allows you to choose the desired thermoforming method for each one: thermoforming, postural or on positive. It also allows individual, rather than simultaneous, programming of workstations, giving multi-practitioner practices the freedom to schedule appointments without having to invest in several machines.